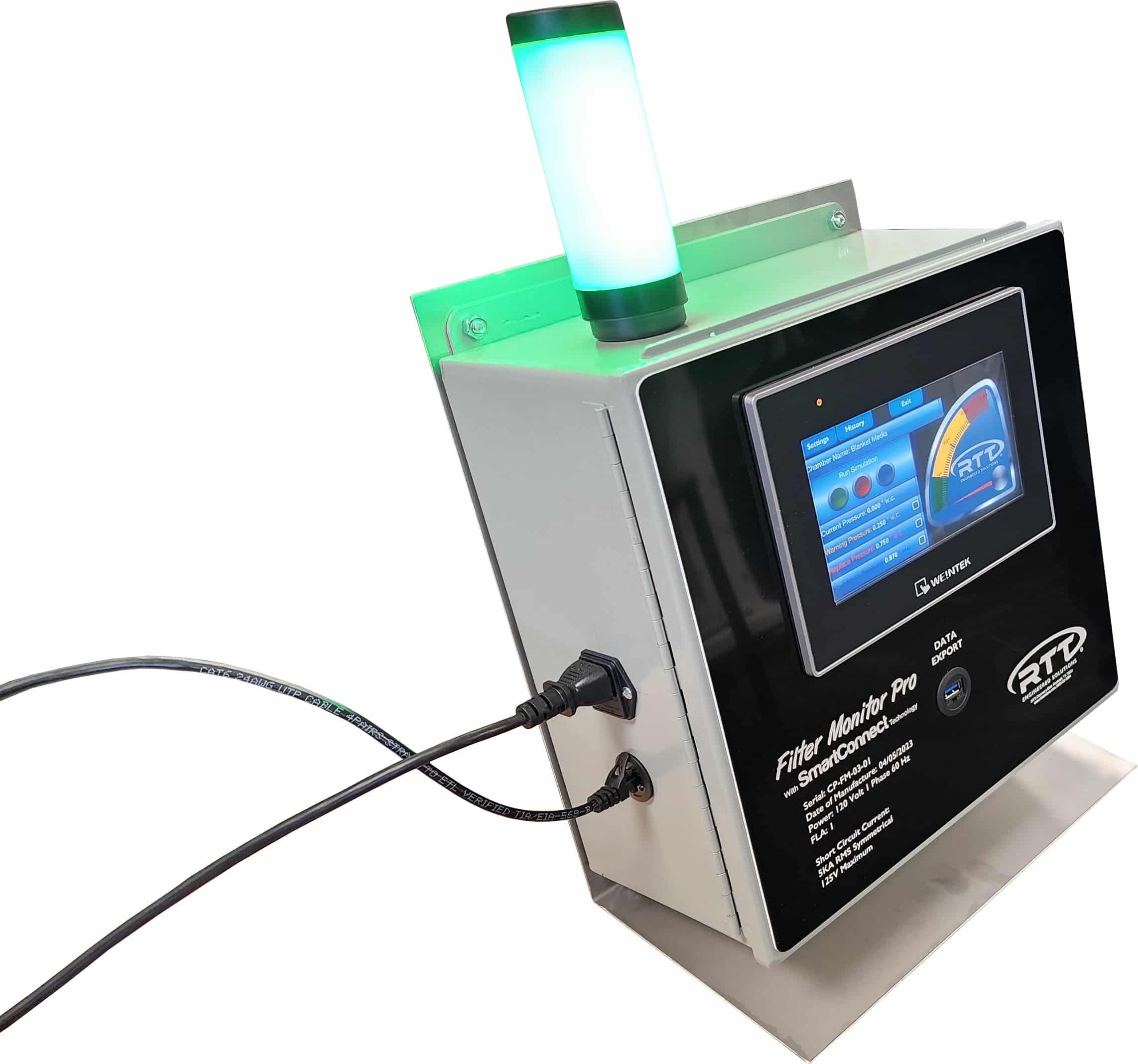

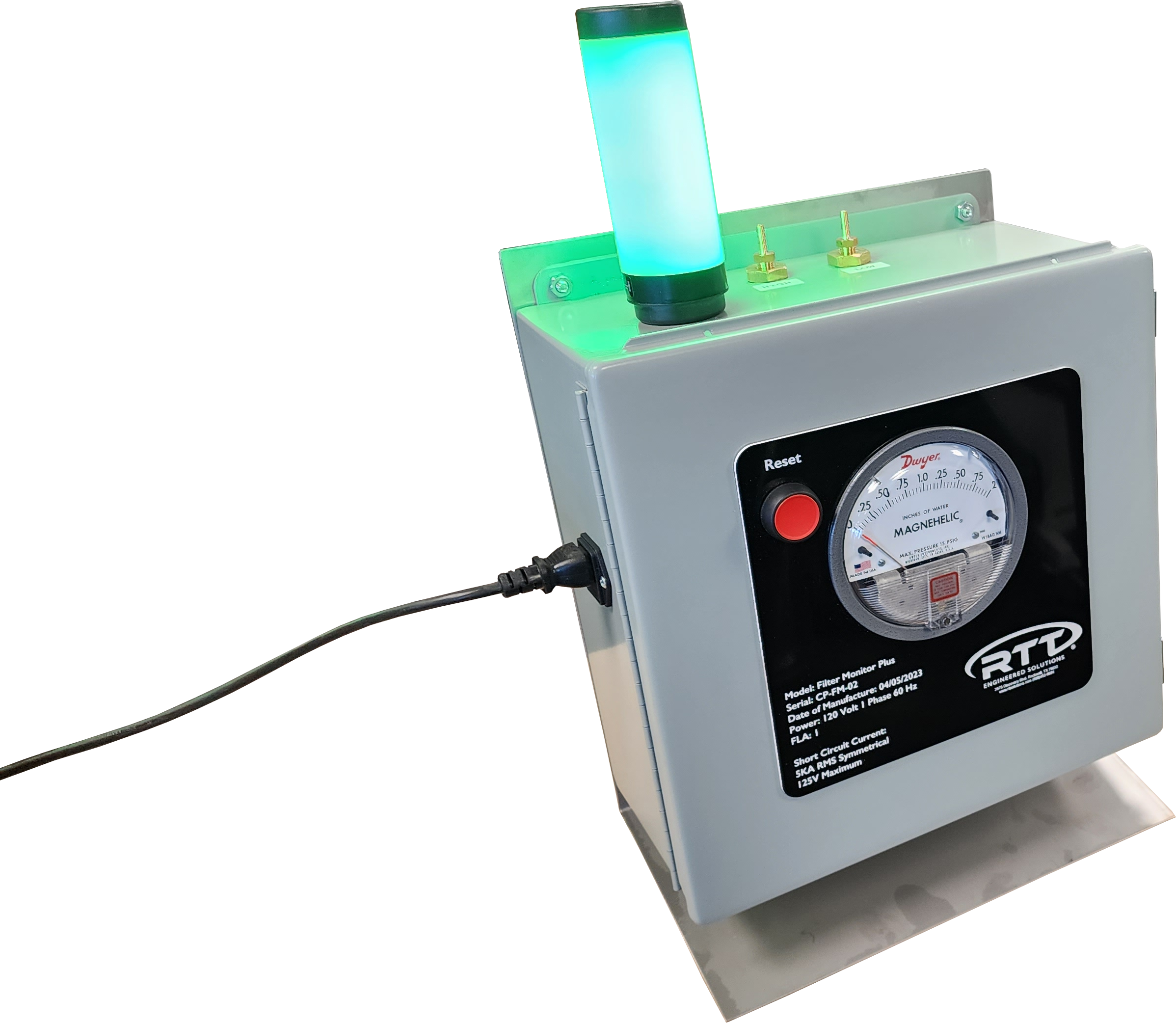

FILTER MONITORING SYSTEMS

The Filter Monitoring System by RTT is used to monitor the condition of the exhaust filters and notifies the status of the filtration to operators, paint line managers, or management teams.

Notifications range from visual indicators on the panel face to emails and text messages depending on the version of monitoring required.

The ability to understand the condition of the exhaust filter load dramatically affects the efficiencies of spray booth operational cost due to unnecessary filter change-outs.

This system is a stand-alone unit that can be added to any existing or new spray booth and powered by a regular 120 volt outlet by using the provided power cable.

Retrofitting capabilities are not just limited to RTT Engineered Solutions equipment but also other manufactures of spray booths.

It is recommended each exhaust chamber is monitored on a spray booth.

Filter Resistance Airflow Control System

The Filter Resistance Airflow Controls System

(FRACS) by RTT is designed to maintain a constant airflow volume for your spray booth exhaust system when the ability to pressurize the booth enclosure is not possible.

This upgrade to the normal RTT control package will autocratically adjust the exhaust fan speed as the exhaust filtration loads.

- Initial FPM set point is setup by using handheld velometer and adjusting panel mounted potentiometer to achieve desired FPM with clean filters.

- Set point potentiometer is mounted inside control cabinet to reduce tampering.

- Transmitter uses 0-10vdc signal to VFD for simple troubleshooting.

- The FRACS can be retrofitted to any existing spray booth with little to no additional components.