Paint Booths in Oklahoma City By RTT Engineered Solutions

RTT Engineered Solutions is an industry leader in paint booth manufacturing. With 24 years of experience, RTT’s extensive line of products are easy to install, made from the highest quality, performance-based components and can be customized to the space or functionality needs.

Paint Booths in Oklahoma City

RTT Engineered Solutions provides the highest quality industrial and automotive paint booths in the industry. Our finishing equipment and systems include paint booths, spray booths, powder coating booths, ovens, and more. We offer paint booths that are fitted for painting for small parts to large equipment such as semi-trucks. RTT also offers custom engineered paint booths to fit your finishing needs.

What Is A Paint Booth?

A paint booth is a contained environment designed to confine and evacuate itemized particulate and vapors within a restricted area. Paint booths are a requirement of OSHA and NFPA standards to prevent overspray and volatiles from migrating and causing unsafe conditions or contamination outside of the designated spray area. The use of a paint booth dramatically improves the outcome of your project due to the exhaust system and filters. In addition to higher quality work, paint booths provide a clean environment in which to paint and minimize contamination in a coated product

RTT Engineered Solutions provides the highest quality industrial and automotive paint booths in the industry. Our finishing equipment and systems include paint booths, spray booths, powder coating booths, ovens, and more. We offer paint booths that are fitted for painting for small parts to large equipment such as semi-trucks. RTT also offers custom engineered paint booths to fit your finishing needs.

Paint booths come in a wide range of sizes and construction.

Some examples of different paint booth variations include:

Batch Ovens

RTT designs and fabricates batch ovens to meet a wide range of industrial curing applications for both liquid and powder coatings. RTT ovens are designed for efficient performance utilizing high-quality direct fired burners. The oven is designed around an internal frame structure which supports prefabricated, insulated oven panels that interlock, simplifying installation. The pretested burner box assembly supplies heated air to ductwork in the side walls of the oven enclosure which exits through “H” nozzles. The design of the internal duct work, combined with dedicated combustion and exhaust blowers, allow for optimal air flow balance within the oven, which equates to quicker ramp up times and faster batch processing.

Batch Powder Booths

With an open front design, RTT’s batch powder booths (also known as a powder coating spray booth) are perfect for low volume powder applications. A cost-effective solution, this booth makes efficient use of shop space and is used for large or small parts. With an open face design and a 3-stage filtration system, air is drawn in through the open front of the spray booth and passes through the booth’s working area into the filtered exhaust plenum. The air is filtered in three stages and discharged back into the room.

- RTT booths are constructed from heavy duty 18-gauge, prime quality galvanized steel and engineered with corresponding support structure.

- All panels and support members are laser cut and precision formed for consistent fit allowing for easy nut and bolt assembly.

- 3-Stage Filtration System is extremely effective at catching powder dust; Stage 1: Blanket style filter, Stage 2: Bag style filter, Stage 3: Hepa type filter.

- Final Filter Proving Assembly ensures filters are installed and functioning properly and interlocks with the air solenoid valve.

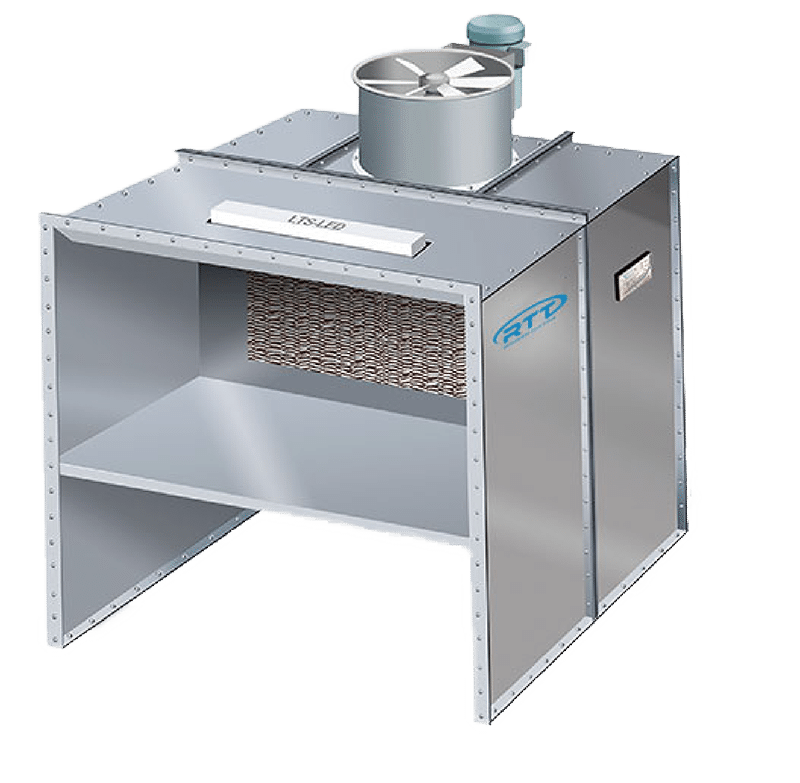

Open Front Bench Booths

RTT’s Open Front Bench Booths offer a safe environment for any type of finishing operation and allows easy paint application for small to medium sized parts. The Open Front Bench Paint Booths are designed for batch type production systems. Many smaller shops favor this model to paint a few small items frequently and maintenance departments utilize this type of booth for every day building repair projects.

Air flows in the open front of the paint booth, passes through the booth’s working area and into the filtered exhaust chamber located in the rear of the booth. This filtered exhaust air is drawn through the exhaust plenum and discharged upward into the atmosphere through the exhaust stack. To make efficient use of your valuable floor space, RTT’s Industrial Paint Booths are available in a range of standard sizes to accommodate your finishing needs. Custom sizes and designs are available to accommodate site specific needs.

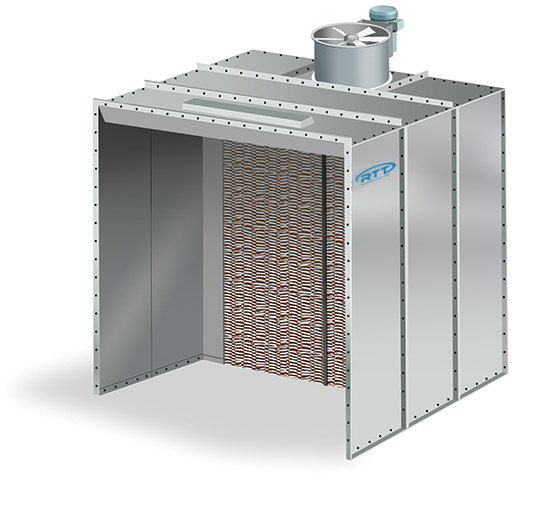

Open Front Booths

Designed for both batch and conveyorized production systems, RTT’s Open Front Paint Booths offer a safe environment for any type of finishing operation. Air flows in the open front of the booth, passes through the booth’s working area and into the filtered exhaust chamber located in the rear of the booth. This filtered exhaust air is drawn through the exhaust plenum and discharged upward into the atmosphere through the exhaust stack. To make efficient use of your valuable floor space, RTT’s Industrial Paint Booths are available in a range of standard sizes to accommodate your finishing needs. Custom sizes and designs are available to accommodate site specific needs including conveyor and crane slots/openings.

RTT booths are easy to install and simple to maintain. The quality and workmanship of RTT spray booths allow us to offer a 5-year warranty when using high performance W-Series RP Arrestor exhaust filters manufactured by RTT Engineered Solutions.

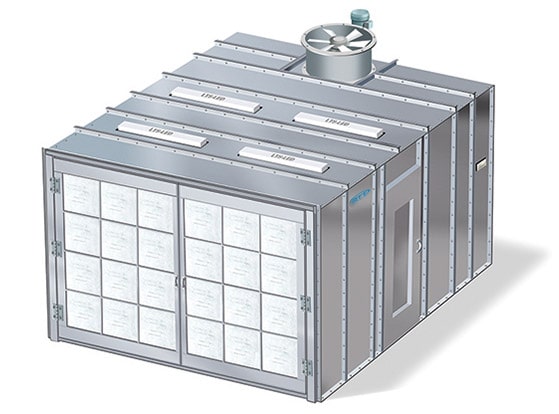

Enclosed Industrial Booths

RTT Enclosed Industrial Paint Booths are designed to produce a high-quality finish in an extremely efficient manner. Air flows in through the filtered double entry doors in the front of the booth, passes through the booth’s working area, and into the filtered exhaust chamber located in the rear of the paint booth. This filtered exhaust air is drawn through the exhaust plenum and discharged upward into the atmosphere through the exhaust stack. To make efficient use of your valuable floor space, RTT’s Enclosed Industrial Paint Booths are available in a range of standard sizes to accommodate your finishing needs. Custom sizes are also available.

RTT booths are easy to install and simple to maintain. The quality and workmanship of RTT spray booths allow us to offer a 5-year warranty when using high performance W-Series RP Arrestor exhaust filters manufactured by RTT.

What Size Paint Booth Do I Need?

Other factors to consider? Give Choosing the right paint booth a read from Products Finishing Magazine Online.

Why RTT?

RTT Engineered Solutions manufactures paint booths for a variety of applications including Industrial Booths, Large Equipment Booths and Automotive Booths. Our short lead times mean you can get up and running with your new RTT paint booth quickly. We provide full transparency with pricing quotes and can work within numerous budget constraints. Not sure what you need? Give us a call and one of our representatives can walk you through the right paint booth application for your industry or click here to send us an email.

RTT’s customer service is unmatched

RTT’s customer service is unmatched in the paint booth industry, and we are the ONLY paint booth manufacturer to offer a 5-year warranty on our spray booths, when used with our RTT high performance RP W-Series exhaust filters. These filters have been designed, tested and approved to provide superior paint particle separation while restricting the least amount of air flow in accordance with ASHRAE 52.1. The RTT RP W-Series filters available in both pad and roll form have been designed to perform well in a wide variety of applications.

DURABLE POWDER COATED WHITE OPTION

Powder coating is a high-quality finish that provides a more durable and attractive finish. Your paint booth will be more resistant to scratches, chips, abrasions, corrosion, fading and other wear issues.

E-LIGHT LED LIGHTS & RETRO KITS

RTT’s E-Light LED lights offer many advantages to fluorescent lamps such as improved durability, an exceptionally longer life span, lower energy usage, reduced maintenance costs and higher safety. Dimmable options available.

BASIC CONTROL PANEL

Motor starters are our most basic and cost-effective option to easily operate the fan on your booth. The motor starter is pre-wired in a NEMA 1 enclosure and is equipped with an adjustable solid-state overload relay and a 4-pole 23-amp contactor. Motor starters can be set up for just about any voltage, phase and HP configuration needed for your application.

TOUCH SCREEN & PLC BASED CONTROLS

RTT offers touch screen controls for our batch ovens, paint booths and powder collectors, allowing for simple operation of your equipment. There are (3) size options to choose from as well as expandable input and outputs, on screen pressure monitoring, precise system information, built-in hour meters, and ethernet communications.

EXHAUST DUCTWORK

We offer High-quality 18-gauge galvanized steel ductwork and other needed accessories to properly exhaust your finishing equipment. The components come in a wide variety of configurations depending on your paint booth structure and features. Our ductwork construction provides superior protection against destructive elements including corrosion and rust.

FILTERED BOOTH DOORS

Fabricated with a tubular steel frame and hung on structural channel jambs, the doors feature integral filter holding cells ready for filter placement. These doors are provided with a foam rubber seal around the perimeter and a rubber sweep seal at the threshold. The mounting hardware provided includes FM approved panic type safety latches and door pulls.